题名:Monitoring flexure behavior of compacted clay beam using high-resolution distributed fiber optic strain sensors

作者:李豪杰, 朱鸿鹄*, 张春新, Reddy, N. G., 吴海颖

来源:Geotechnical Testing Journal, 2022, 45(3), 627-643.

1 概述

OFDR分布式光纤应变测量技术已被广泛应用于结构健康监测领域,如桥梁、管道以及大坝等构筑物的变形监测,但应用于土体变形监测的研究较少。本文借助压实黏土梁四点弯曲试验,通过在土体内部植入应变感测光缆,监测土体内部的变形信息,验证了OSI分布式光纤感测技术应用于土体变形测量的可行性,并讨论了实际工程应用中存在的关键问题。

2 测试过程

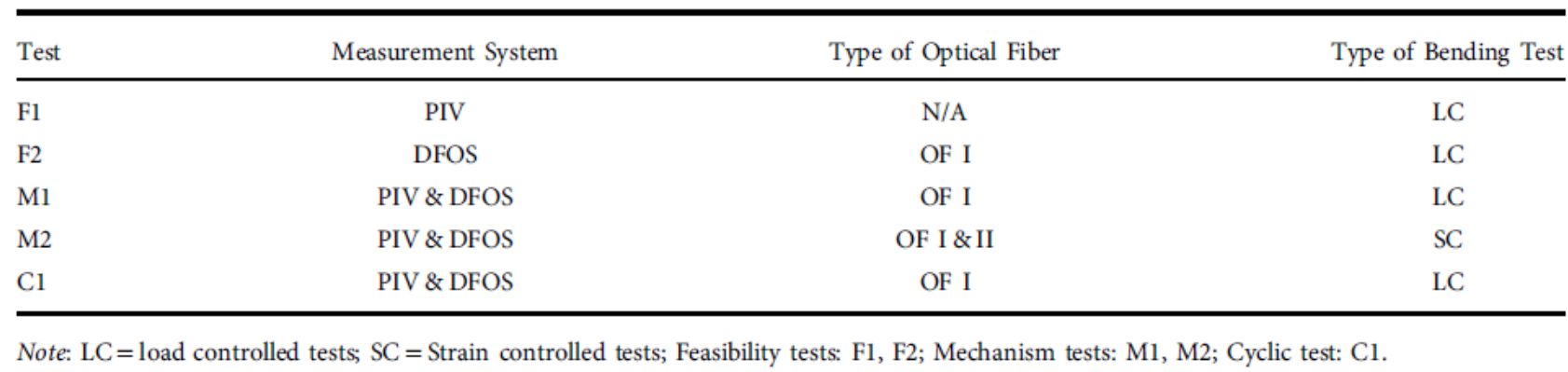

本文所用压实黏土梁长360mm、横截面80mm。当黏土梁堆积至20、40和60mm的高度(在图1中标记为H1、H2和H3)时,将光纤铺设在模型上表面,然后通过侧壁上的通孔连接到OSI解调仪。光纤在安装过程中需保持轻微的拉伸,以提高其对压缩变形的敏感性。

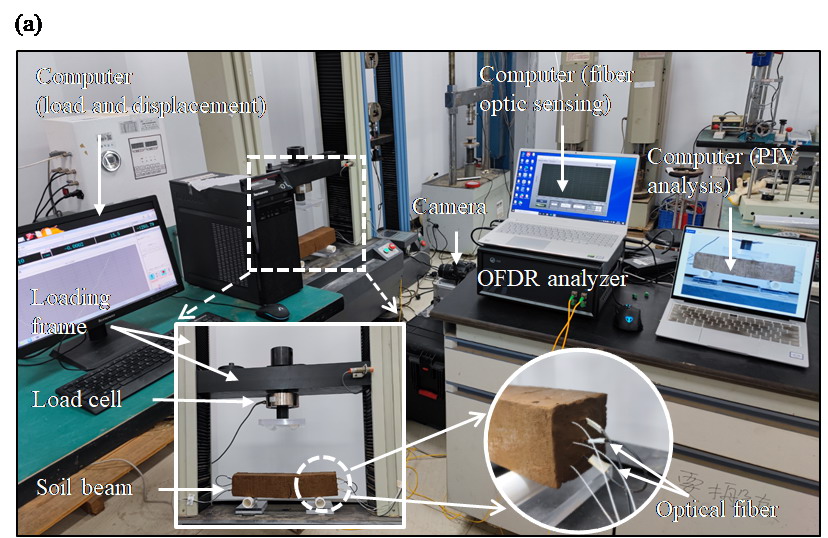

(A) 试验装置图;(B) 试验装置及监测方案示意图 (单位:mm)

图1 弯曲试验装置

试验装置如图1所示,试验详情见表1。C1测试研究黏土在加载-卸载条件下的力学行为。此外,对M1组中每级加载后的应变进行了两次采集,两次读数的间隔是三分钟。

表1 试验方案

3 测试结果

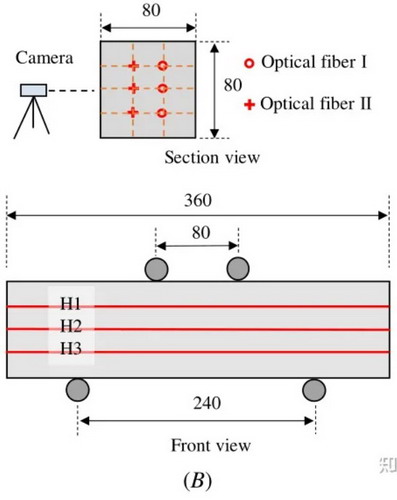

梁在特定位置的应变分布如图2所示,传感光纤的位置和选定的分析点如图2D所示。

图2 土梁ML1的应变发展过程

图2 土梁ML1的应变发展过程

(A)H1;(B)H2;(C)H3;(D)兴趣点和光纤位置示意图

在初始加载阶段,黏土的压缩应变随荷载呈线性增加。中性轴上方的黏土处于压缩状态,而下方处于拉伸状态,中性轴位于半高以下,随着载荷的增加,中性轴上移。

当加载到62.75N时,H1的应变测量值急剧下降,随后裂纹萌生。H2层在初始阶段处于压缩状态,表明中性轴低于半高。H3的应变测量如图2C所示。140、180和220mm处的拉伸应变的变化趋势与100mm和260mm处的不同。这种差异也被认为是由应力集中造成的。

当荷载达到62.75N时,梁的底部开始产生拉裂,并延伸到梁的顶部。由于传感光纤与周围土体之间的耦合减弱,拉应变的增加受到了限制。随后,拉伸区发生塑性变形,拉伸区范围逐渐扩大,呈现为中性轴上移。随着荷载的持续增加,拉伸区的黏土达到其屈服点。之后,梁底部出现裂缝。

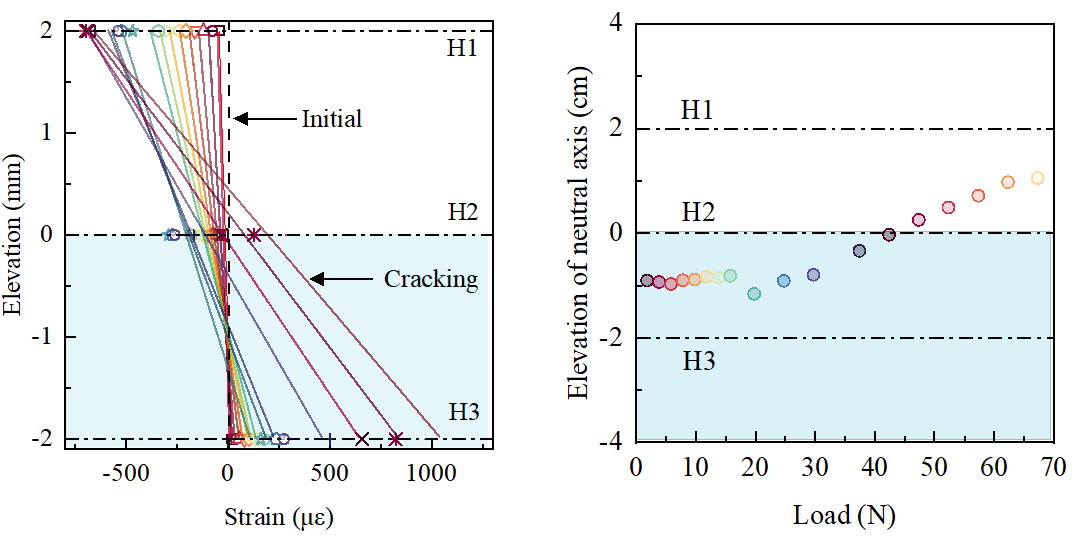

图3 中性轴定位 (土梁ML1)

(A)根据线弹性分布模型处理应变测量结果;(B)中性轴的定位

梁跨中的应变测量如图3A所示,根据线弹性分布理论,中性轴位置在数值上等于图3A所示拟合线上横坐标等于零的点的纵坐标。图3B显示了随着载荷的增加中性轴向上的移动。发现当载荷达到20N时发生,其开始移动,这与土梁内部应变测量结果和挠度观察结果是一致的。当载荷达到40N时,中性轴上升到梁的中间深度。中性轴的高度与开裂前的荷载成线性关系。试验中,黏土在每一级荷载下的应变都被记录两次,并用同一级荷载下两个读数间的差值来描述黏土变形的稳定性,利用光纤的响应来确定黏土在压缩和拉伸状态下的蠕变特性。

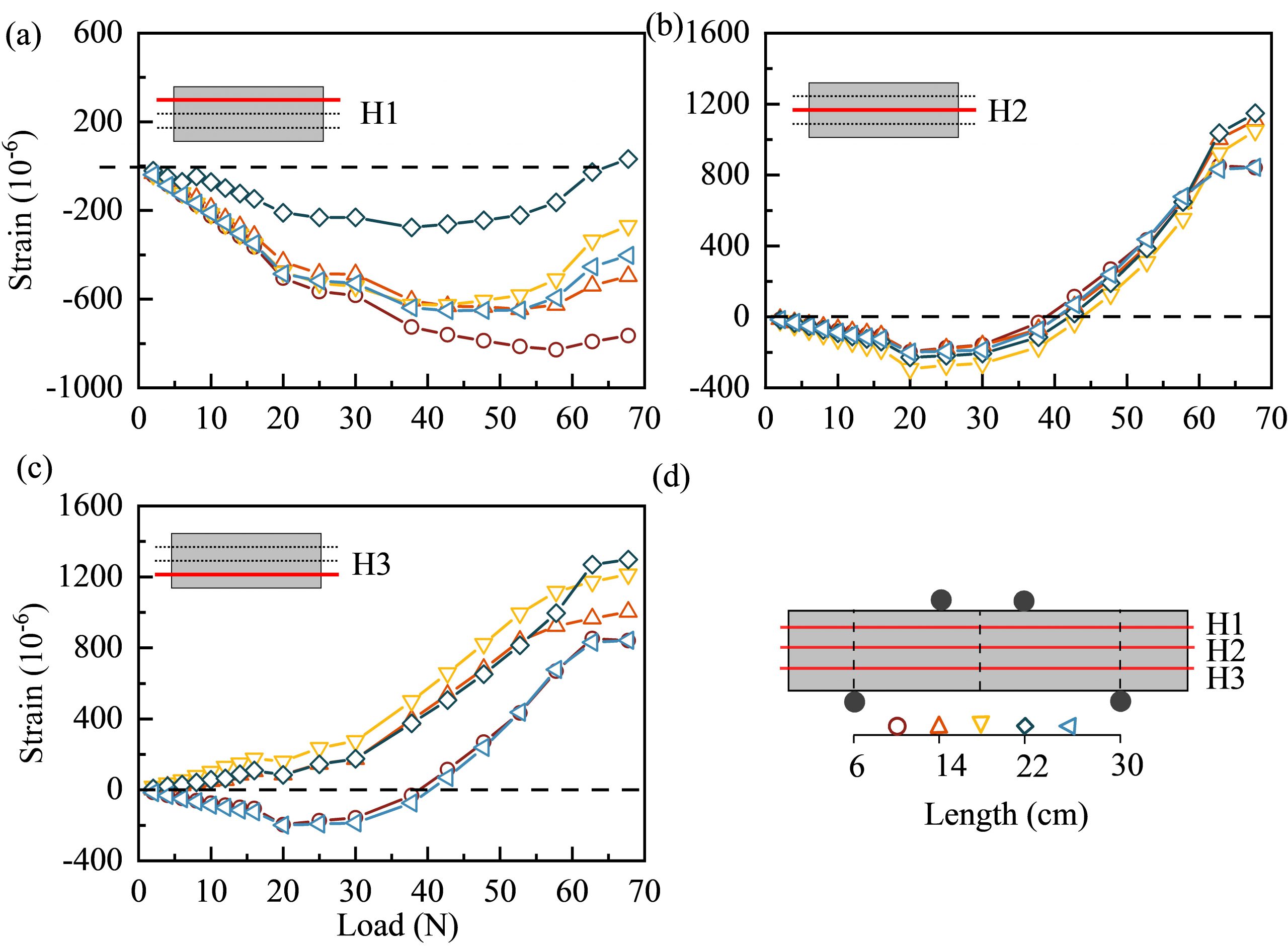

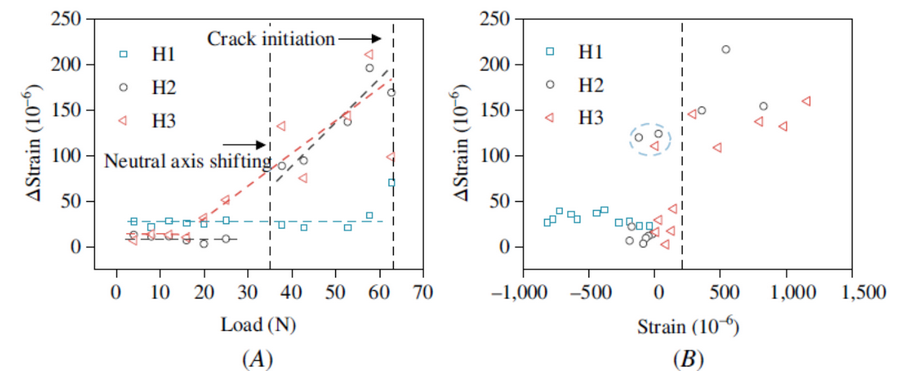

图4 (A)应变读数差随荷载的变化;(B) 应变读数差与累积应变之间的关系

如图4A所示,黏土在应变变化在开裂前稳定在25-33με,张拉变形区在20N之前表现出相同的趋势,之后迅速增大。当H2处于压缩状态时,其在加载初期的应变差异很小。然而,当载荷接近40N时, H2从压缩变为拉伸。H2的应变差迅速增大。当载荷达到20N时,H3层的蠕变速率迅速增加,而H1层的蠕变速率在整个加载阶段相对较慢。

4 试验结论

对内部植入了应变感测光纤的压实黏土梁进行了一系列四点弯曲试验,阐明了基于OFDR 技术的DSS方案用于土体开裂和变形测量中的可行性和独特优势,并对光纤在弹塑性和蠕变变形监测中的性能进行了初步探讨。与张拉变形监测相比,光纤在黏土压缩回弹变形监测中的准确度较低。光纤的瞬时应变测量表明,黏土在压缩状态下的蠕变速率比在拉伸状态下的蠕变速率更稳定。

参考文献

-

- ASTM C880 / C880M, 2016. ASTM designation: ASTM C880/C880M-15 Standard Test Method for Flexural Strength of Dimension Stone, ASTM International, West Conshohocken, PA, 2015, www.astm.org

- Anggraini, V., Asadi, A., Syamsir, A., and Huat, B. B. 2017. “Three point bending flexural strength of cement treated tropical marine soil reinforced by lime treated natural fiber.” Measurement 111: 158-166. https://doi.org/10.1016/j.measurement.2017.07.045

- Antunes, P., Lima, H., Varum, H., and André, P. 2012. “Optical fiber sensors for static and dynamic health monitoring of civil engineering infrastructures: Abode wall case study.” Measurement 45, no. 7: 1695-1705. https://doi.org/10.1016/j.measurement.2012.04.018

- Berrocal, C. G., Fernandez, I., & Rempling, R. 2021. “Crack monitoring in reinforced concrete beams by distributed optical fiber sensors.” Structure and Infrastructure Engineering, 17(1), 124-139. https://doi.org/10.1080/15732479.2020.1731558

- Baker, R. 1981. “Tensile strength, tension cracks, and stability of slopes.” Soils Found 21, no. 2: 1-17. https://doi.org/10.3208/sandf1972.21.2_1

- British Standards Institute. 1983. “116 testing concrete-method for determination of compressive strength of concrete cubes.” British Standards Institute. London, United Kingdom.

- Camp, S., Gourc, J., and Ple, O. 2010. “Landfill clay barrier subjected to cracking: Multi-scale analysis of bending tests.” Appl Clay Sci 48, no. 3: 384-392. https://doi.org/10.1016/j.clay.2010.01.011

- Costa, Y. D., Zornberg, J. G., & Costa, C. M. 2021. “Physical modeling of buried PVC pipes overlying localized ground subsidence. ” Acta Geotech, 16(3), 807-825. https://doi.org/10.1007/s11440-020-01058-9

- Iten, M., Schmid, A., Hauswirth, D., and Puzrin, A. M. 2009. “Defining and monitoring of landslide boundaries using fiber optic systems.” Proceedings of the Prediction and Simulation Methods for Geohazard Mitigation, Kyoto, S, 451-456.

- Kim, T., Kim, C., Jung, S., and Lee, J. H. 2007. “Tensile strength characteristics of contaminated and compacted sand-bentonite mixtures.” Environ Geol 52, no. 4: 653-661. https://doi.org/10.1007/s00254-006-0494-8

- Lakshmikantha, M. R., Prat, P. C., Ledesma, A. 2009. “Image Analysis for the Quantification of a Developing Crack Network on a Drying Soil”. Geotechnical Testing Journal 32, no. 6: 505-515.

- Li, J., and Zhang, L. 2011. “Study of desiccation crack initiation and development at ground surface.” Eng Geol 123, no. 4: 347-358. https://doi.org/10.1016/j.enggeo.2011.09.015

- Lin, H., Xiong, W., Yan, Q. 2016. “Three-Dimensional Effect of Tensile Strength in the Standard Brazilian Test Considering Contact Length” Geotechnical Testing Journal 39, no. 1: 137-143. https://doi.org/10.1520/GTJ20140268

- Ling, D., Xu, Z., Cai, W., and Wang, Y. 2015. “Experimental study on characteristics of bending cracks of compacted soil beams.” Chin J Geotech Eng 37: 1165-1172. https://doi.org/ 10.11779/CJGE201507001

- Luyckx, G., Voet, E., De Waele, W., and Degrieck, J. 2010. “Multi-axial strain transfer from laminated CFRP composites to embedded Bragg sensor: I. Parametric study.” Smart Mater Struct 19, no. 10: 105017. https://doi.org/10.1088/0964-1726/19/10/105017

- Mendez, A., Morse, T. F., and Mendez, F. 1990. “Applications of embedded optical fiber sensors in reinforced concrete buildings and structures.” Proc., Fiber optic smart structures and Skins II, International Society for Optics and Photonics, 60-69.

- Miller, C. J., Mi, H., and Yesiller, N. 1998. “Experimental analysis of desiccation crack propagation in clay liners 1.” J Am Water Resour Assoc., 34, no. 3: 677-686. https://doi.org/10.1111/j.1752-1688.1998.tb00964.x

- Naruse, H., Uehara, H., Deguchi, T., Fujihashi, K., Onishi, M., Espinoza, R., Guzman, C., Pardo, C., Ortega, C., and Pinto, M. 2007. “Application of a distributed fibre optic strain sensing system to monitoring changes in the state of an underground mine.” Meas Sci Technol 18, no. 10: 3202. https://doi.org/10.1088/0957-0233/18/10/S23

- Schenato, L., Palmieri, L., Camporese, M., Bersan, S., Cola, S., Pasuto, A., Galtarossa, A., Salandin, P., and Simonini, P. 2017. “Distributed optical fibre sensing for early detection of shallow landslides triggering.” Sci Rep 7, no. 1: 14686. https://doi.org/10.1038/s41598-017-12610-1

- Tang, C.-S., Shi, B., Cui, Y.-J., Liu, C., and Gu, K. 2012. “Desiccation cracking behavior of polypropylene fiber–reinforced clayey soil.” Can Geotech J 49, no. 9: 1088-1101. https://doi.org/10.1139/t2012-067

- Thusyanthan, N., Take, W., Madabhushi, S., and Bolton, M. 2007. “Crack initiation in clay observed in beam bending.” Géotechnique 57, no. 7: 581-594. https://doi.org/10.1680/geot.2007.57.7.581

- van Ravenzwaaij, J., Iten, M., Spruit, R., and de Boer, A. 2018. “Geotechnical and structural applications of fiber-optic sensing.” High Tech Concrete: Where Technology and Engineering Meet. Springer 1287-1298. https://doi.org/10.1007/978-3-319-59471-2_149

- Verstrynge, E., De Wilder, K., Drougkas, A., Voet, E., Van Balen, K., and Wevers, M. 2018. “Crack monitoring in historical masonry with distributed strain and acoustic emission sensing techniques.” Constr Build Mater 162: 898-907. https://doi.org/10.1016/j.conbuildmat.2018.01.103

- Viswanadham, B., Jha, B., and Pawar, S. 2010. “Influence of geofibers on the flexural behavior of compacted soil beams.” Geosynth Int 17, no. 2: 86-99. https://doi.org/10.1680/gein.2010.17.2.86

- Wan, K. T., Leung, C. K., and Olson, N. G. 2008. “Investigation of the strain transfer for surface-attached optical fiber strain sensors.” Smart Mater Struct 17, no. 3: 035037. https://doi.org/10.1088/0964-1726/17/3/035037

- White, D., Take, W., and Bolton, M. 2003. “Soil deformation measurement using particle image velocimetry (PIV) and photogrammetry.” Géotechnique 53, no. 7: 619-631. https://doi.org/10.1680/geot.2003.53.7.619

- Wong, C. K., Wan, R. G., and Wong, R. C. 2017. “Tensile and shear failure behaviour of compacted clay–hybrid failure mode.” Int J Geotech Eng 1-11. https://doi.org/10.1080/19386362.2017.1408242

- Wu, H., Zhu H.-H., Zhang C.-C., Zhou G.-Y., Zhu, B., Zhang, W., Mohammad Azarafza. 2020. “Strain integration-based soil shear displacement measurement using high-resolution strain sensing technology.” Measurement, 166:108210. https://doi.org/10.1016/j.measurement.2020.108210.

- Zhang, C.-C., Zhu, H.-H., Liu, S., Shi, B., and Cheng, G. 2019. “Quantifying progressive failure of micro-anchored fiber optic cable–sand interface via high-resolution distributed strain sensing.” Can Geotech J, 57(6): 871-881. https://doi.org/10.1139/cgj-2018-0651

- Zhang, C.-C., Zhu, H.-H., Shi, B., She, J.-K., and Zhang, D. 2016. “Performance evaluation of soil-embedded plastic optical fiber sensors for geotechnical monitoring.” Smart Struct Syst 17, no. 2: 297-311. https://doi.org/ 10.12989/sss.2016.17.2.297

- Zhang, C. C., Zhu, H. H., Chen, D. D., Xu, X. Y., Shi, B., & Chen, X. P. 2018. “Feasibility study of anchored fiber-optic strain-sensing arrays for monitoring soil deformation beneath model foundation. ” Geotechnical Testing Journal, 42(4), 966-984. https://doi.org/10.1520/GTJ20170321

- Zhu, H.-H., Shi, B., Zhang, J., Yan, J.-F., and Zhang, C.-C. 2014. “Distributed fiber optic monitoring and stability analysis of a model slope under surcharge loading.” J Mt Sci 11, no. 4: 979-989. https://doi.org/10.1007/s11629-013-2816-0

- Ziegler, S., Leshchinsky, D., Ling, H. I., and Perry, E. B. 1998. “Effect of short polymeric fibers on crack development in clays.” Soils Found 38, no. 1: 247-253. https://doi.org/10.3208/sandf.38.247