作者:高宇新,朱鸿鹄*,张春新,刘 威,王 静,张 巍

(南京大学地球科学与工程学院,江苏 南京 210023)

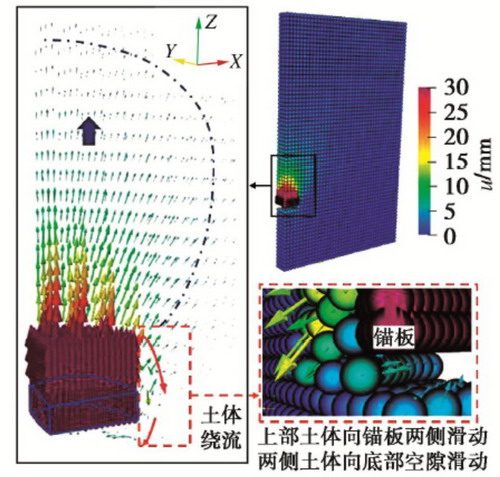

摘 要:土体中锚板的上拔过程存在复杂的锚土相互作用,掌握其变形及破坏机制对于确定锚板的极限承载力和优化设计具有重要的意义。采用三维物质点法(MPM)模拟了砂土中圆形锚板的上拔过程,探究了不同埋深条件下土体的位移场分布及锚板的上拔破坏机制,并结合极限平衡法研究了砂土密实度、锚板尺寸和埋深等因素对其极限承载力的影响。结果表明,临界埋深比主要受土体性质影响,受锚板直径的影响较小。当埋深比小于临界埋深比时,土体表现为浅埋破坏,破坏面延伸至地表,其形状在松砂中为圆台状,在密砂中为曲面状;当埋深比大于临界埋深比时,土体中的破坏面呈灯泡状,且不延展至地表。当上拔位移较大时,锚板上方出现土体绕流现象 。保持埋深比不变,锚板直径越大,则极限承载力越大,上拔承载力系数越小。砂土密实度对锚板上拔力–位移曲线有较大的影响,密砂中的极限承载力明显大于松砂,且两者的差值随埋深比的增加而增大。

关键词:物质点法;锚板;破坏面;极限承载力;相互作用

Three-dimensional uplift simulation of anchor plates in sand using material point method

GAO Yu-xin, ZHU Hong-hu, ZHANG Chun-xin, LIU Wei, WANG Jing, ZHANG Wei

(School of Earth Science and Engineering, Nanjing University, Nanjing 210023, China)

Abstract: There are complex anchor-soil interactions in the uplift process of the anchor plate, and it is of great significance to master the deformation mechanism and displacement distribution of the soil to predict the uplift bearing capacity and optimize the design. Based on the three-dimensional material point method (MPM) to simulate the uplift of the anchor plate, the uplift failure mechanism under different embedment depth ratios is explored, and the influences of soil compactness, diameter and embedment depth ratio of the anchor plate on the peak bearing capacity are analyzed using limit equilibrium method. The results show that the limit embedment depth ratio is mainly affected by the nature of the soil, but less affected by the diameter. When the embedment depth ratio is less than the critical one, the soil exhibits shallow embedment failure, and the failure surface extends to the surface. Its shape is truncated cone-shaped in loose sand and curved in dense sand. When the embedment depth ratio is greater than the critical one, the damage surface in the soil is bulb-shaped and does not extend to the surface. When the uplift displacement is large, the soil above the anchor plate appears to flow around. When the embedment depth ratio remains unchanged, the larger the plate diameter, the greater the ultimate bearing capacity, and the smaller the uplift bearing capacity coefficient. Considering the softening effects, the load-displacement response in the uplift process of loose sand and dense sand is different. The ultimate bearing capacity of the dense sand is greater than that of the loose sand, and the difference between them increases with the increase of the embedment depth ratio.

Key words: material point method; anchor plate; failure plane; ultimate bearing capacity; interaction

参考文献:

[1] ADAMS J I, HAYES D C. The uplift capacity of shallow foundations[J]. Ontario Hydro Research Quarterly, 1967, 19: 1.

[2] ILAMPARUTHI K, DICKIN E A, MUTHUKRISNAIAH K. Experimental investigation of the uplift behaviour of circular plate anchors embedded in sand[J]. Canadian Geotechnical Journal, 2002, 39(3): 648–664.

[3] 胡 伟, 刘顺凯, 邹贵华, 等. 竖向条形锚定板水平拉拔极限承载力统一理论解研究[J]. 岩土工程学报, 2018, 40(2): 296–304. (HU Wei, LIU Shun-kai, ZOU Gui-hua, et al. Unified theoretical solution for ultimate bearing capacity of

vertical strip anchor[J]. Chinese Journal of Geotechnical Engineering, 2018, 40(2): 296–304. (in Chinese))

[4] 黄茂松, 余生兵. 基于块体集上限法的砂土中条形锚板抗拔承载力分析[J]. 岩土工程学报, 2013, 35(2): 201–207. (HUANG Mao-song, YU Sheng-bing. Pull-out capacity of strip anchor plate in sand based on block set mechanism[J]. Chinese Journal of Geotechnical Engineering, 2013, 35(2): 201–207. (in Chinese))

[5] 郝冬雪, 符胜男, 陈 榕, 等. 砂土中锚板拉拔模型试验及其抗拔力计算[J]. 岩土工程学报, 2015, 37(11): 2101–2106. (HAO Dong-xue, FU Sheng-nan, CHEN Rong, et al. Experimental investigation of uplift behavior of anchors and estimation of uplift capacity in sands[J]. Chinese Journal of Geotechnical Engineering, 2015, 37(11): 2101–2106. (in Chinese))

[6] SAKAI T, TANAKA T. Experimental and numerical study of uplift behavior of shallow circular anchor in two-layered Sand[J]. Journal of Geotechnical & Geoenvironmental Engineering, ASCE, 2007, 133(4): 469–478.

[7] PEREZ Z A, SCHIAVON J A, TSUHAC C D H C, et al. Numerical and experimental study on influence of installation effects on behaviour of helical anchors in very dense sand[J]. Canadian Geotechnical Journal, 2018, 55: 1067–1080.

[8] KANITZ M, HAGER A, GRABE J, et al. Numerical and experimental analysis of the extraction mechanism of an anchor plate embedded in saturated sand[J]. Computers and Geotechnics, 2019, 111: 191–201.

[9] EVANS T M, ZHANG N. Three-dimensional simulations of plate anchor pullout in granular materials[J]. International Journal of Geomechanics, ASCE, 2019, 19(4): 04019004.

[10] LIANG W J, ZHAO J D, SOGA K. Multiscale modeling of anchor pull-out in sand[C]// Proceedings of International Conference of the International Association for Computer Methods and Advances in Geomechanics, Lecture Notes in Civil Engineering, 2021, 125: 787–793.

[11] ZHANG X, CHEN Z, LIU Y. The Material Point Method: A Continuum-Based Particle Method for Extreme Loading Cases[M]. Academic Press, Oxford, 2017.

[12] FERN E J, ROHE A, SOGA K, et al. The material point method for geotechnical engineering: a practical guide[M]. Boca Raton: CRC Press, 2019.

[13] 刘 春, 乐天呈, 施 斌, 等. 颗粒离散元法工程应用的三大问题探讨[J]. 岩石力学与工程学报, 2020, 39(6): 1142–1152. (LIU Chun, LE Tian-cheng, SHI Bin, et al. Discussion on three major problems of engineering application of the particle discrete element method[J]. Chinese Journal of Rock Mechanics and Engineering, 2020, 39(6): 1142–1152. (in Chinese))

[14] BEUTH L, BENZ T, VERMEER P A. Large deformation analysis using a quasi-static material point method[J]. Journal of Theoretical and Applied Mechanics, 2008, 38(1–2), 45–60.

[15] SULSKY D, CHEN Z, Schreyer H L. A particle method for history-dependent materials[J]. Computer Methods in Applied Mechanics and Engineering, 1994, 118(1–2): 179–196.

[16] SULSKY D, ZHOU S J, SCHREYER H L. Application of a particle-in-cell method to solid mechanics[J]. Computer Physics Communications, 1995; 87: 236–252.

[17] 史卜涛, 张 云, 张 巍. 边坡稳定性分析的物质点强度折减法[J]. 岩土工程学报, 2015, 38(9): 1678–1684. (SHI Bo-tao, ZHANG Yun, ZHANG Wei. Strength reduction material point method for slope stability[J]. Chinese Journal of Geotechnical Engineering, 2015, 38(9): 1678–1648. (in Chinese))

[18] 孙玉进, 宋二祥. “12·20”深圳滑坡动态模拟[J]. 岩土工程学报, 2018, 40(3): 441–448. (SUN Yu-jin, SONG Er-xiang. Dynamic simulation of “12·20” Shenzhen landslide[J]. Chinese Journal of Geotechnical Engineering, 2018, 40(3): 441–448. (in Chinese))

[19] 张春新, 朱鸿鹄, 李豪杰, 等. 支护压力控制下隧道周围砂土变形破坏物质点法模拟. 浙江大学学报(工学版)[J], 2021, 55(7): 1317–1326. (ZHANG Chun-xin, ZHU Hong-hu, LI Hao-jie, et al. Material point method simulations of sand deformation and failure around tunnel controlled by support pressure. Journal of Zhejiang University(Engineering Science)[J], 2021, 55(7): 1317–1326. (in Chinese))

[20] 张芮瑜, 孙玉进, 宋二祥. 强夯的物质点法模拟及其能量转化规律分析[J]. 岩土工程学报, 2019, 41(7): 1206–1216. (ZHANG Rui-yu, SUN Yu-jin, SONG Er-xiang. Simulation of dynamic compaction using material point method and analysis of its energy conversion law[J]. Chinese Journal of Geotechnical Engineering, 2019, 41(7): 1206–1216.(in Chinese))

[21] 张春新, 朱鸿鹄, 周谷宇, 等. 落球检测技术的三维物质点法模拟研究[J]. 防灾减灾工程学报, 2021, 41(2): 311–320. (ZHANG Chun-xin, ZHU Hong-hu, ZHOU Gu-yu, et al. Simulation of Falling Ball Test using Three⁃Dimensional Material Point Method[J]. Journal of Disaster Prevention and Mitigation Engineering, 2021, 41(2): 311–320. ( in Chinese))

[22] COETZEE C J, VERMEER P A, BASSON A H. The modelling of anchors using the material point method[J]. International Journal for Numerical and Analytical Methods in Geomechanics, 2005, 29(9): 879–895.

[23] CECCATO F, BISSON A, COLA S. Large displacement numerical study of 3D plate anchors[J]. European Journal of Environmental and Civil Engineering, 2020, 24(4): 520–538.

[24] 陈 榕, 符胜男, 郝冬雪, 等. 密砂中圆形锚上拔力尺寸效应分析[J]. 岩土工程学报, 2019, 41(1): 78–85. (CHEN Rong, FU Sheng-nan, HAO Dong-xue, et al. Scale effects of uplift capacity of circular anchors in dense sand[J]. Chinese Journal of Geotechnical Engineering, 2019, 41(1): 78–85. (in Chinese))

[25] FERN E J, DE LANGE D A, ZWANENBURG C, et al. Experimental and numerical investigations of dyke failures involving soft materials[J]. Engineering Geology, 2017, 219: 130–139.

[26] FERN E J, SOGA K. The role of constitutive models in MPM simulations of granular column collapses[J]. Acta Geotechnica, 2016, 11 (3): 659–678.

[27] 蔡正银. 砂土的渐进破坏及其数值模拟[J]. 岩土力学, 2008, 35(3): 580–585. (CAI Zheng-yin. Progressive failure of sand and its numerical simulation[J]. Rock and Soil Mechanics, 2008, 35(3): 580–585. (in Chinese))

[28] BOLTON M D. Strength and dilatancy of sands[J]. Géotechnique, 1986, 36(1): 65–78.

[29] 朱 泳, 朱鸿鹄, 李 飞, 等. 砂土中水平锚板抗拔特性试验研究[J]. 中南大学学报(自然科学版), 2018, 25(7): 1768–1774. (ZHU Yong, ZHU Hong-hu, LI Fei, et al. Experimental study on uplift behavior of anchor plate in sand[J]. Journal of Central South University (Science and Technology), 2018, 25(7): 1768–1774. (in Chinese))

[30] 张 昕, 乐金朝, 刘明亮, 等. 砂土中锚板的抗拔机理与承载力计算模型研究[J]. 岩土工程学报, 2012, 34(9): 1734–1739. (ZHANG Xin, YUE Jin-chao, LIU Ming-liang, et al. Pullout Capacity of Plate Anchor in Sand by Laboratory Test[J]. Chinese Journal of Geotechnical Engineering, 2012, 34(9): 1734–1739. (in Chinese))

[31] 郝冬雪, 岳 冲, 陈 榕, 等.常压至高压下中砂剪切特性及应力-剪胀关系[J]. 岩土工程学报, 2020, 42(04): 765–772. (HAO Dong-xue, YUE Chong, CHEN Rong, et al. Shear characteristics and stress-dilation relation of medium sandunder normal to high pressures[J]. Chinese Journal of Geotechnical Engineering, 2020, 42(04): 765–772.(in Chinese))

[32] SAEEDY H S. Stability of circular vertical anchors[J]. Canadian Geotechnical Journal, 1987, 24(3): 452–456.

[33] MURRAY E J, GEDDES J D. Uplift of anchor plates in sand[J]. Journal of Geotechnical Engineering, ASCE, 1987, 113(3): 202–215.

[34]. LIU J, LIU M, ZHU Z. Sand deformation around an uplift plate anchor[J]. Journal of Geotechnical and Geoenvironmental Engineering, ASCE, 2012, 138(6): 728–737.

[35]桂美兵. 砂土中锚板抗拔承载力室内试验研究[D]. 合肥工业大学, 2020. (GUI Mei-bing. Pullout capacity of plate anchor in sand by laboratory test[D]. Hefei University of Technology, 2020. (in Chinese))

[36] SAKAI T, TANAKA T. Scale effect of a shallow circular anchor in dense sand[J]. Soils and Foundations, 1998, 38(2): 93–99.

[37] 史旦达, 毛逸瑶, 杨 勇, 等. 基于DIC技术的砂土中圆形锚板上拔土体变形特性试验研究[J]. 岩土力学, 2020, 41(10):27–39. (SHI Dan-da, MAO Yi-yao, YANG Yong, et al. Experimental study on the deformation characteristics of soils around uplift circular plate anchors using digital image correlation technology[J]. Rock and Soil Mechanics, 2020, 41(10):27–39. (in Chinese))

[38] 倪钰菲, 乔仲发, 朱 泳, 等. 基于粒子图像测速的锚板抗拔破坏机理试验研究[J]. 土木与环境工程学报(中英文), 2020, 42(1): 24–30. (NI Yu-fei, QIAO Zhong-fa, ZHU Yong, et al. Experimental study on uplift failure of anchor plate based on PIV technology[J]. Journal of Civil and Environmental Engineering, 2020, 42(1): 24–30. (in Chinese))

[39] CHEUK C Y, BOLTON M D, WHITE D J. The uplift resistance of pipes and plate anchors buried in sand[J]. Géotechnique, 2008, 58(10):771–779.