【研究背景】

随着城市化的加速推进,土地资源日益紧张,城市建设对地块的需求不断攀升。面对这一趋势,新的建筑结构不得不频繁在覆盖有地下管道的区域中兴建,这无疑给地下管道的结构完整性评估与基础工程设计带来了前所未有的挑战。尤其是在管道与建筑物交互作用的复杂环境中,传统的评估方法可能不再适用,迫切需要新的技术和方法来确保工程安全与管道的长期运营稳定性。然而,目前的研究在此领域尚存在不足,对于高密度建筑环境下管道安全的系统性研究和综合性评估方法开发尚处于起步阶段。

【研究内容】

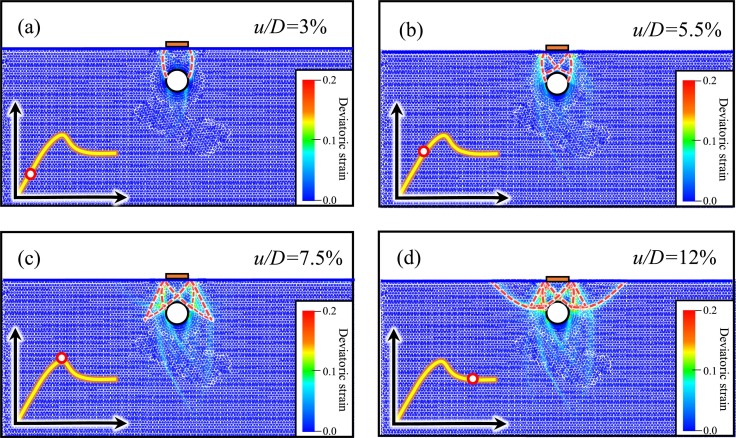

南京大学朱鸿鹄教授团队采用物质点法(MPM)开展了一系列数值模拟研究,深入探讨了地面载荷诱发的埋地管道-地基土相互作用,特别是埋管地基的失效机理和土压力分布情况。本文通过将模拟结果与现有文献中的实验数据进行对比,验证了所提数值模型的准确性。本研究细致考察了埋置深度比和管道至载荷水平距离比对地基失效机制的影响,发现随着这两个比值的增加,管土系统的承载力得到了显著提升。特别是当水平距离比超过3或埋置深度比达到4时,管道对整体承载能力的贡献边际递减。此外,模拟结果显示,管土系统的失效模式随水平距离的增加从普朗特尔型基础失效转变为不对称失效模式。外部载荷的大小和管道的具体埋置位置均对管道周边土压力分布产生显著影响。研究还揭示了管土界面作为潜在滑移面的作用,以及其对剪切带可能产生的吸力效应。本文的分析结果为理解管土系统的失效模式提供了新的见解,对于地下管道和基础设施的设计与优化具有重要的参考价值。

论文详细分析了埋置比和水平距离比对失效机理的影响。结果表明,随着埋置比和水平距离比的增加,管土系统的承载力显著增加。当水平距离比大于3或埋置比达到4时,管道对承载能力的影响变得微不足道。随着水平距离的增加,管土系统的失效模式从普朗特尔型基础失效转变为不对称失效。外部载荷和管道的埋藏位置都会影响管道周围的土压力分布。管土界面可以为基础失效提供潜在的滑动面,并且可能对剪切带产生吸力效应。最后,文章提出了管土系统的失效模式的理解,以供地下管道和基础系统的设计使用。

【研究意义】

本文采用物质点法开展数值模拟研究,深入分析了地表载荷下埋地管道和地基土的相互作用。研究发现,随着管道埋置比和水平距离比的增加,管土系统的承载力显著增加。这一研究结果对于地下管道和基础系统的设计具有重要意义。此外,本文还归纳总结了管土系统的多种失效模式,为相关的防灾减灾工程提供了新的思路。

题名:Modeling pipe-soil interaction under surface loading using material point method

作者:Xie T.-C.; Zhu H.-H.; Tan D.-Y.; Kumar Shukla S.

来源:Tunnelling and Underground Space Technology, 147 (2024) 105709.

出版时间:2024-04-01·

DOI:10.1016/j.tust.2024.105709

References

Adams, D.N., Muindi, T., Selig E.T., 1989. Polyethylene Pipe under High Fill, Transportation Research Record, 1231, National Research Council, Washington, D.C., 88-95.

Al-Kafaji, I.K.J., 2013. Formulation of a dynamic material point method (MPM) for geomechanical problems. PhD thesis. University of Stuttgart, Germany.

Anura3D, 2019. Anura3D MPM software v. 2019. http://www.anura3d.com.

Barclay, P.L., Waters, J., Zhang, D.Z., 2023. Large deformation and brittle failure calculated using the dual-domain material point method. Comput. Part. Mech. 1-15.

Bardenhagen, S.G., Brackbill, J.U., Sulsky, D., 2000. The material-point method for granular materials. Comput. Methods Appl. Mech. Eng. 187 (3-4), 529-541.

Beuth, L., 2012. Formulation and Application of a Quasi-Static Material Point Method, Ph.D. thesis, University of Struttgart, Germany.

Bildik, S., Laman, M., 2015. Experimental investigation of the effects of pipe location on the bearing capacity. Geomech. Eng. 8(2), 221-235.

Bildik, S., Laman, M., 2019. Experimental investigation of soil-structure-pipe interaction. KSCE J. Civ. Eng. 23 (9), 3753–3763.

Bolton, M.D., 1986. The strength and dilatancy of sands. Geotechnique 36 (1), 65-78.

Ceccato, F., Beuth, L., Vermeer, P.A., Simonini, P., 2016. Two-phase Material Point Method applied to the study of cone penetration, Comput. Geotech. 80, 440-452.

Chaloulos, Y.K., Bouckovalas, G.D., Karamitros, D.K., 2017. Trench effects on lateral py relations for pipelines embedded in stiff soils and rocks. Comput. Geotech. 83, 52-63.

Chen, Y., Zhao, W., Han, J., Jia, P., 2019. A CEL study of bearing capacity and failure mechanism of strip footing resting on c-φ soils. Comput. Geotech. 111, 126-136.

Conte, E., Pugliese, L., Troncone, A., 2020. Post-failure analysis of the Maierato landslide using the material point method. Eng. Geol. 277, 105788.

Durgunoglu, H.T., Mitchell, J.K., 1973. Static penetration resistance of soils. Space Sciences Laboratory, Berkeley, California.

Fern, E.J., de Lange, D.A., Zwanenburg, C., Teunissen, J.A.M., Rohe, A., Soga, K., 2017. Experimental and numerical investigations of dyke failures involving soft materials. Eng. Geol. 219, 130-139.

Fern, E.J., Soga, K., 2016. The role of constitutive models in MPM simulations of granular column collapses. Acta Geotech. 11 (3), 659-678.

Fern, J., Rohe, A., Soga, K., Alonso, E., 2019. The Material Point Method for Geotechnical Engineering: a practical guide. CRC Press, Boca Raton.

Gao, L., Liao, D., Mo, P.Q., 2023. Modeling footing resting on anisotropic sand using material point method, J. Rock Mech. Geotech. Eng. 15 (12) 3271-3290.

Goodarzi, M., Rouainia, M., 2017. Modelling slope failure using a quasi-static MPM with a non-local strain softening approach. Proc. Eng. 175, 220-225.

Gu, W., Wu, K., Tong, L., Liu, S., 2022. Study of deflection of buried HDPE corrugated pipeline under the uneven settlement of soil. KSCE J. Civ. Eng. 26(1), 221-235.

Huang, B., Liu, J., Fan, J., Ling, D., 2021. Experimental study on uplift mechanisms of pipes buried in sloping medium dense sand. J. Pipeline Syst. Eng. Pract. 12(3), 04021027.

Jiang, M., Zhang, W.; Wang; J., Zhu, H., 2015. DEM analyses of an uplift failure mechanism with pipe buried in cemented granular ground. Inter. J. Geomech. 15 (5), 04014083.

Kazi, M., Shukla, S.K., Habibi, D., 2016. Behaviour of an embedded footing on geotextile-reinforced sand. Proc. Inst. Civil Eng.-Ground Improv. 169 (2), 120-133.

Khan, M.U.A., Shukla S.K., 2021. Numerical investigation of the structural response of a conduit buried within a soil slope. Transp. Geotech. 30, 100614.

Khan, M.U.A., Shukla, S.K., 2020. Load–settlement response and bearing capacity of a surface footing located over a conduit buried within a soil slope. Int. J. Geomech. 20 (10), 04020173.

Khan, M.U.A., Shukla, S.K., Paraskeva, T.S., 2022. Stress distribution around the conduit buried within a soil slope–An experimental investigation. Transp. Geotech. 32, 100687.

Kou, Y., Shukla, S.K., Mohyeddin, A., 2018. Experimental investigation for pressure distribution on flexible conduit covered with sandy soil reinforced with geotextile reinforcement of varying widths. Tunn. Undergr. Space Technol. 80, 151-163.

Kouretzis, G.P., Krabbenhøft, K., Sheng, D., Sloan, S.W., 2014. Soil-buried pipeline interaction for vertical downwards relative offset. Can. Geotech. J. 51 (10), 1087-1094.

Li, B., Fang, H., Yang, K., Zhang, X., Du, X., Wang, N., Guo, X., 2022. Impact of erosion voids and internal corrosion on concrete pipes under traffic loads. Tunn. Undergr. Space Technol. 130, 104761.

Li, Z.Y., Huang, H.W., Zhou, M.L., Zhang, D.M., 2023b. Failure responses of rock tunnel faces during excavation through the fault-fracture zone. Undergr. Space, 10, 166–181.

Liang, W., Wu, H., Zhao, S., Zhou, W., Zhao, J., 2022. Scalable three‐dimensional hybrid continuum‐discrete multiscale modeling of granular media. Int. J. Numer. Methods Eng. 123(12), 2872-2893.

Marston, A., 1930. The theory of external loads on closed conduits in the light of the latest experiments. Bulletin No. 96, Iowa Engineering Experiment Station, Ames, Iowa.

Martinelli, M., Galavi, V., 2021. Investigation of the material point method in the simulation of cone penetration tests in dry sand. Comput. Geotech. 130, 103923.

Martinelli, M., Galavi, V., 2022. An explicit coupled MPM formulation to simulate penetration problems in soils using quadrilateral elements. Comput. Geotech. 145, 104697.

Moore, I.D., 1985. Analytical theory for buried tube postbuckling. J. Eng. Mech. 111 (7), 936-951.

Nguyen, H.C., Vo-Minh, T., 2022. The use of the node-based smoothed finite element method to estimate static and seismic bearing capacities of shallow strip footings. J. Rock Mech. Geotech. Eng. 14(1), 180-196.

Ni, P.P., Qin, X.G., Yi, Y., 2018. Numerical study of earth pressures on rigid pipes with tire-derived aggregate inclusions. Geosynth. Int. 25 (5), 494–506.

Noh, W.F., 1963. CEL: A time-dependent, two-space-dimensional, coupled Eulerian-Lagrange code. Academic Press, New York, US.

Oswell, J.M., Hart, J., Zulfiqar, N., 2019. Effect of geotechnical parameter variability on soil-pipeline interaction. J. Pipeline Syst. Eng. Pract. 10 (4), 04019028.

Peng, S., Liao, W., Liu, E., 2020. Pipe–soil interaction under the rainfall-induced instability of slope based on soil strength reduction method. Energy Rep. 6, 1865-1875.

Roy, K., Hawlader, B., Kenny, S., Moore, I., 2018a. Uplift failure mechanisms of pipes buried in dense sand. Int. J. Geomech. 18 (8), 04018087.

Roy, K., Hawlader, B., Kenny, S., Moore, I., 2018b. Upward pipe–soil interaction for shallowly buried pipelines in dense sand. J. Geotech. Geoenviron. Eng. 144 (11), 04018078.

Simpson, B., Hoult, N.A., Moore, I.D., 2015. Distributed sensing of circumferential strain using fiber optics during full-scale buried pipe experiments. J. Pipeline Syst. Eng. Pract. 6 (4), 04015002.

Soga, K., Alonso, E., Yerro, A., Kumar, K., Bandara, S., 2016. Trends in large-deformation analysis of landslide mass movements with particular emphasis on the material point method. Geotechnique. 66 (3), 248–273.

Terzaghi, K., 1943. Theoretical Soil Mechanics. Wiley, New York.

Trautmann, C.H., 1983. Behavior of pipe in dry sand under lateral and uplift loading. PhD thesis. Cornell University, New York.

Troncone, A., Pugliese, L., Conte, E., 2022a. Analysis of an excavation-induced landslide in stiff clay using the material point method. Eng. Geol. 296, 106479.

Troncone, A., Pugliese, L., Parise, A., Conte, E., 2022b. A simple method to reduce mesh dependency in modelling landslides involving brittle soils. Géotechn. Lett. 12(3), 167-173.

Wang, D.Y., Zhu, H.H., Wang, B.J., Shi, B., 2021. Performance evaluation of buried pipe under loading using fiber Bragg grating and particle image velocimetry techniques. Measurement. 186, 110086.

Wang, B., Vardon, P. J., Hicks, M. A., Chen, Z., 2016. Development of an implicit material point method for geotechnical applications. Comput. Geotech. 71, 159-167.

Wang, D.Y., Zhu, H.H., Wang, J., Sun, Y.J. Schenato, L., Pasuto, A., Shi, B., 2023. Characterization of sliding surface deformation and stability evaluation of landslides with fiber–optic strain sensing nerves. Eng. Geol. 314, 107011.

Wang, L., Coombs, W.M., Augarde, C.E., Cortis, M., Brown, M.J., Brennan, A.J., Knappett, J.A., Davidson, C., Richards, D., White, D.J., Blake, A.P., 2021b. An efficient and locking-free material point method for three-dimensional analysis with simplex elements. Int. J. Numer. Methods Eng. 122(15), 3876-3899.

Wu, J., Kouretzis, G., Suwal, L., 2021. Bearing capacity mechanisms for pipes buried in sand. Can. Geotech. J. 58 (6), 834-847.

Xie, T.C., Zhu, H.H., Zhang, C.X., Zhang, W., 2023. Modeling strip footings on slopes using the material point method. Bull. Eng. Geol. Environ. 82 (4), 99.

Xie, T.C., Zhu, H.H., Zhang, C.X., Liu, W., Tan, D.Y., Zhang, W., 2024. Modeling Pipe–Soil Interaction under Lateral Movement Using Material Point Method. J. Pipeline Syst. Eng. Pract. 15(1), 04023058.

Ye, X., Zhu, H.H., Cheng, G., Pei, H.F., Shi, B., Schenato, L., Pasuto, A., 2023. Thermo-hydro-poro-mechanical responses of a reservoir-induced landslide tracked by high-resolution fiber optic sensing nerves. J. Rock Mech. Geotech. Eng. In press. https://doi.org/10.1016/j.jrmge.2023.04.004

Ye, X., Zhu, H.H., Wang, J., Zhang, Q., Shi, B., Schenato, L., Pasuto, A., 2022. Subsurface multi‐physical monitoring of a reservoir landslide with the fiber‐optic nerve system. Geophys. Res. Lett. 49 (11), e2022GL098211.

Yerro, A., 2015. MPM modeling of landslides in brittle and unsaturated soils. PhD thesis. UPC, Barcelona.

Yimsiri, S., Soga, K., Yoshizaki, K., Dasari, G.R., O’Rourke, T.D., 2004. Lateral and upward soil-pipeline interactions in sand for deep embedment conditions. J. Geotech. Geoenviron. Eng. 130 (8), 830-842.

Yost, K.M., Yerro, A., Green, R.A., Martin, E., Cooper, J., 2022. MPM modeling of cone penetrometer testing for multiple thin-layer effects in complex soil stratigraphy. J. Geotech. Geoenviron. Eng. 148 (2), 04021189.

Zhang, C.X., Zhu, H.H., Li, H., 2023. Modeling pipe-soil interaction under vertical downward relative offset using B-spline material point method. J. Rock Mech. Geotech. Eng. 15(6), 1520-1534.

Zhang, C.X., Zhu, H.H., Zhang, W., Li, H.J., Liu, W., 2022. Modeling uplift failure of pipes buried in sand using material point method. Tunn. Undergr. Space Technol. 119, 104203.

Zhang, X., Chen, Z., Liu, Y., 2017. The material point method: A continuum-based particle method for extreme loading cases. Academic Press, Oxford.

Zhu, H.H., Wang, D.Y., Shi, B., Wang, X., Wei, G.Q., 2022. Performance monitoring of a curved shield tunnel during adjacent excavations using a fiber optic nervous sensing system. Tunn. Undergr. Space Technol. 124, 104483.

Zhu, H.H., Xie, T.C., Zhang, W., Shukla, S.K., 2023. Numerical simulations of a strip footing on the soil slope with a buried pipe using the material point method. Inter. J. Geomech, 23(11): 04023190.