【研究背景】

在易发生地质灾害的地区,地下管道的过度侧向运动经常会危及管道的结构完整性和可靠性,同时也会对周围的地质环境安全造成威胁。然而,目前研究领域中缺乏对于管土相互作用的深入研究,这也是本篇论文主要要解决的问题。

【研究内容】

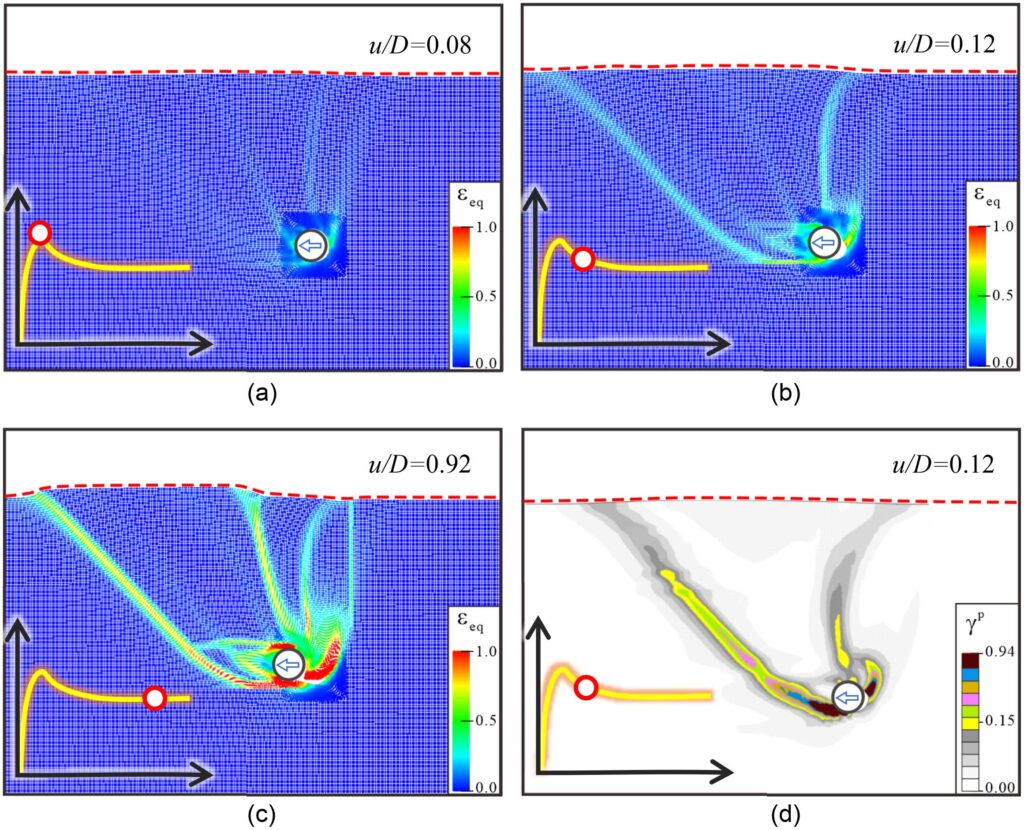

本文基于材料点法(MPM)对管土相互作用进行了研究,重点关注了在管道侧向运动过程中,周围土壤在破坏后阶段的失效机制。通过与文献中大型模型试验结果的比较,验证了数值模型的准确性。研究分析了埋深、管径和土壤密度等因素对失效机制的影响,并发现在浅埋管道条件下,一般剪切破坏往往会导致地面隆起;随着管道埋深的增加,峰值土壤阻力也相应增加,并逐渐从一般剪切破坏转变为局部流动机制。此外,管径较小、埋深较大的条件下,峰值阻力后的软化效应减小。通过比较失效模式,发现嵌入比是管土相互作用模式的主要决定因素,而与土壤密度的影响相比较小。最后,本文探讨了预测土壤峰值侧向阻力的方法,以辅助地下管道的设计。

【研究意义】

本文采用MPM方法对管土相互作用进行了深入研究,揭示了在地下管道侧向运动中,周围土壤的失效机制和相关因素的影响规律,为地下管道的设计和安全运行提供了重要的理论支持。此外,本文提出了预测土壤峰值侧向阻力的方法,具有一定的实际应用价值。

来源:J. Pipeline Syst. Eng. Pract., ASCE

作者:Xie, Tian-Cheng, Zhu, Honghu, Zhang, Chunxin, Liu, Wei, Tan, Daoyuan

作者单位:南京大学

出版时间:2024-1-1

论文DOI:10.1061/jpsea2.pseng-1498

Modeling Pipe-Soil Interaction under Lateral Movement Using Material Point Method

Abstract: Excessive lateral movements of buried pipes in geohazard-prone areas frequently jeopardize the structural integrity and serviceability of pipelines, as well as the safety of the surrounding geoenvironments. Based on the material point method (MPM), this paper investigates the pipe-soil interactions under lateral pipe movements, with a focus on the failure mechanisms of the surrounding soil during post-failure stages. The accuracy of the numerical model is validated by comparison with the results of large-scale model tests in the literature. There is a strong correlation between the experimental and numerical results in terms of force-displacement relationships and soil failure patterns. The impacts of burial depths, pipe diameters, and soil densities on the failure mechanism are analyzed in detail. The results showed that general shear failure tends to occur in shallow pipe conditions, resulting in significant ground heave. As the pipe burial depth increases, the peak soil resistance increases accordingly, and a transition from general shear failure to a localized flow-around mechanism gradually evolves. Furthermore, the softening effect after the peak resistance is reduced under the smaller pipe diameter and greater buried depth conditions. Comparisons of failure patterns illustrate that the embedment ratio is the main determinant of pipe-soil interaction modes as compared with the soil density. Transition failure often occurs when the embedment ratio ranges from 4.5 to 9.5, with slight influences from pipe diameters and soil properties. Finally, the prediction of the soil peak lateral resistance is explored to assist in underground pipeline design.

Keywords: Pipe–soil interaction; Failure mode; Material point method (MPM); Soil resistance; Lateral movement

References

Akhtar, S., and B. Li. 2020. “Numerical analysis of pipeline uplift resistance in frozen clay soil considering hybrid tensile-shear yield behaviors.” Int. J. Geosynth. Ground Eng. 6: 1–12. https://doi.org/10.1007/s40891-020-00228-9.

ALA (American Lifelines Alliance). 2005. Guidelines for the design of buried steel pipe. Washington, DC: ALA.

Audibert, J. M., and K. J. Nyman. 1977. “Soil restraint against horizontal motion of pipes.” J. Geotech. Eng. Div. 103 (10): 1119–1142. https://doi.org/10.1061/AJGEB6.0000500.

Bardenhagen, S. G., J. U. Brackbill, and D. Sulsky. 2000. “The material point method for granular materials.” Comput. Methods Appl. Mech. Eng. 187 (3–4): 529–541. https://doi.org/10.1016/S0045-7825(99)00338-2.

Bhandari, T., F. Hamad, C. Moormann, K. G. Sharma, and B. Westrich. 2016. “Numerical modelling of seismic slope failure using MPM.” Comput. Geotech. 75 (Mar): 126–134. https://doi.org/10.1016/j.compgeo.2016.01.017.

Bhattacharya, P., and S. Sahoo. 2020. “Pullout resistance of buried pipeline in cohesionless soil nearby sloping ground.” J. Pipeline Syst. Eng. Pract. 11 (2): 04020008. https://doi.org/10.1061/(ASCE)PS.1949-1204.0000450.

Bolton, M. D. 1986. “The strength and dilatancy of sands.” Géotechnique 36 (1): 65–78. https://doi.org/10.1680/geot.1986.36.1.65.

Ceccato, F., L. Beuth, P. A. Vermeer, and P. Simonini. 2016. “Two-phase material point method applied to the study of cone penetration.” Comput. Geotech. 80 (Mar): 440–452. https://doi.org/10.1016/j.compgeo.2016.03.003.

CEN (European Committee for Standardization). 2004. Eurocode 7: Geotechnical design–part 1: General rules. Brussels, Belgium: CEN.

Chaloulos, Y. K., G. D. Bouckovalas, and D. K. Karamitros. 2017. “Trench effects on lateral p-y relations for pipelines embedded in stiff soils and rocks.” Comput. Geotech. 83 (Mar): 52–63. https://doi.org/10.1016/j.compgeo.2016.10.018.

Chaloulos, Y. K., G. D. Bouckovalas, S. D. Zervos, and A. L. Zampas. 2015. “Lateral soil–pipeline interaction in sand backfill: Effect of trench dimensions.” Comput. Geotech. 69 (Sep): 442–451. https://doi.org/10.1016/j.compgeo.2015.05.014.

Chen, Y.,W. Zhao, J. Han, and P. Jia. 2019. “ACEL study of bearing capacity and failure mechanism of strip footing resting on c-φ soils.” Comput. Geotech. 111 (Jul): 126–136. https://doi.org/10.1016/j.compgeo.2019.03.015.

Conte, E., L. Pugliese, and A. Troncone. 2019. “Post-failure stage simulation of a landslide using the material point method.” Eng. Geol. 253 (Apr): 149–159. https://doi.org/10.1016/j.enggeo.2019.03.006.

Conte, E., L. Pugliese, and A. Troncone. 2020. “Post-failure analysis of the Maierato landslide using the material point method.” Eng. Geol. 277: 105788. https://doi.org/10.1016/j.enggeo.2020.105788.

Courant, R., K. Friedrichs, and H. Lewy. 1967. “On the partial difference equations of mathematical physics.” IBM J. Res. Dev. 11 (2): 215–234. https://doi.org/10.1147/rd.112.0215.

Dickin, E. A., and C. F. Leung. 1983. “Centrifugal model tests on vertical anchor plates.” J. Geotech. Eng. 109 (12): 1503–1525. https://doi.org/10.1061/(ASCE)0733-9410(1983)109:12(1503).

di Prisco, C., and A. Galli. 2006. “Soil-pipe interaction under monotonic and cyclic loads: Experimental and numerical modelling.” In Proc., 1st Euro-Mediterranean Symp. on Advances in Geomaterials and Structures. Tunis, Tunisia: LGC-ENIT.

Fern, E. J., A. Rohe, K. Soga, and E. Alonso. 2019. The material point method for geotechnical engineering: A practical guide. Boca Raton, FL: CRC Press.

Fern, E. J., and K. Soga. 2016. “The role of constitutive models in MPM simulations of granular column collapses.” Acta Geotech. 11 (3): 659–678. https://doi.org/10.1007/s11440-016-0436-x.

Gan, Y., Z. Sun, Z. Chen, X. Zhang, and Y. Liu. 2018. “Enhancement of the material point method using B-spline basis functions.” Int. J. Numer. Methods Eng. 113 (3): 411–431. https://doi.org/10.1002/nme.5620.

Guo, P. 2005. “Numerical modeling of pipe–soil interaction under oblique loading.” J. Geotech. Geoenviron. Eng. 131 (2): 260–268. https://doi.org/10.1061/(ASCE)1090-0241(2005)131:2(260).

Guo, P. J., and D. F. E. Stolle. 2005. “Lateral pipe–soil interaction in sand with reference to scale effect.” J. Geotech. Geoenviron. Eng. 131 (3): 338–349. https://doi.org/10.1061/(ASCE)1090-0241(2005)131:3(338).

Honegger, D., and D. J. Nyman. 2004. Guidelines for the seismic design and assessment of natural gas and liquid hydrocarbon pipelines. Arlington, VA: Pipeline Research Council International.

Hsu, T.W. 1996. “Soil restraint against oblique motion of pipelines in sand.” Can. Geotech. J. 33 (1): 180–188. https://doi.org/10.1139/t96-034.

Huang, B., J. Liu, J. Fan, and D. Ling. 2021. “Experimental study on uplift mechanisms of pipes buried in sloping medium dense sand.” J. Pipeline Syst. Eng. Pract. 12 (3): 04021027. https://doi.org/10.1061/(ASCE)PS.1949-1204.0000567.

Huang, B., J. Liu, D. Ling, and Y. Zhou. 2015. “Application of particle image velocimetry (PIV) in the study of uplift mechanisms of pipe buried in medium dense sand.” J. Civ. Struct. Health Monit. 5 (5): 599–614. https://doi.org/10.1007/s13349-015-0130-y.

Janbu, N. 1963. “Soil compressibility as determined by oedometer and triaxial tests.” In Vol. 1 of Proc., European Conf. on Soil Mechanics and Foundation Engineering (ECSMFE), 19–25. Wiesbaden, Germany: Scispace.

Jung, J. K., T. D. O’Rourke, and C. Argyrou. 2016. “Multi-directional force-displacement response of underground pipe in sand.” Can. Geotech. J. 53 (11): 1763–1781. https://doi.org/10.1139/cgj-2016-0059.

Jung, J. K., T. D. O’Rourke, and N. A. Olson. 2013. “Lateral soil-pipe interaction in dry and partially saturated sand.” J. Geotech. Geoenviron. Eng. 139 (12): 2028–2036. https://doi.org/10.1061/(ASCE)GT.1943-5606.0000960.

Katebi, M., D. Wijewickreme, P. Maghoul, and K. Roy. 2021. “Lateral force–displacement response of buried pipes in slopes.” Géotechnique 73 (5): 375–387. https://doi.org/10.1680/jgeot.21.00057.

Kouretzis, G. P., D. Sheng, and S. W. Sloan. 2013. “Sand–pipeline–trench lateral interaction effects for shallow buried pipelines.” Comput. Geotech. 54 (Oct): 53–59. https://doi.org/10.1016/j.compgeo.2013.05.008.

Li, H. J., H. H. Zhu, Y. H. Li, C. X. Zhang, and B. Shi. 2022. “Experimental study on uplift mechanism of pipeline buried in sand using high-resolution fiber optic strain sensing nerves.” J. Rock Mech. Geotech. Eng. 14 (4): 1304–1318. https://doi.org/10.1016/j.jrmge.2022.04.009.

Li, W. L., N. Guo, Z. X. Yang, and T. Helfer. 2021. “Large-deformation geomechanical problems studied by a shear-transformation-zone model using the material point method.” Comput. Geotech. 135 (Mar): 104153. https://doi.org/10.1016/j.compgeo.2021.104153.

Li, Z., K. Soga, and P. Wright. 2015. “Long-term performance of cast-iron tunnel cross passage in London clay.” Tunnelling Underground Space Technol. 50 (Aug): 152–170. https://doi.org/10.1016/j.tust.2015.07.005.

Morshed, M. D. A., K. Roy, and B. Hawlader. 2020. “Modeling of buried pipelines in dense sand for oblique movement in vertical-lateral plane.” J. Pipeline Syst. Eng. Pract. 11 (4): 04020050. https://doi.org/10.1061/(ASCE)PS.1949-1204.0000499.

Mühlhaus, H. B., and I. Vardoulakis. 1987. “The thickness of shear bands in granular materials.” Géotechnique 37 (3): 271–283. https://doi.org/10.1680/geot.1987.37.3.271.

Ni, P. P., X. G. Qin, and Y. Yi. 2018. “Numerical study of earth pressures on rigid pipes with tire-derived aggregate inclusions.” Geosynth. Int. 25 (5): 494–506. https://doi.org/10.1680/jgein.18.00013.

PRCI (Pipeline Research Council International). 2017. Pipeline seismic design and assessment guideline. PR-268-134501-R01. Houston: PRCI.

Roy, K., B. Hawlader, S. Kenny, and I. Moore. 2016. “Finite element modeling of lateral pipeline–soil interactions in dense sand.” Can. Geotech. J. 53 (3): 490–504. https://doi.org/10.1139/cgj-2015-0171.

Roy, K., B. Hawlader, S. Kenny, and I. Moore. 2018. “Uplift failure mechanisms of pipes buried in dense sand.” Int. J. Geomech. 18 (8): 04018087. https://doi.org/10.1061/(ASCE)GM.1943-5622.0001226.

Shi, B., Y. Zhang, and W. Zhang. 2019. “Run-out of the 2015 Shenzhen landslide using the material point method with the softening model.” Bull. Eng. Geol. Environ. 78 (2): 1225–1236. https://doi.org/10.1007/s10064-017-1167-4.

Shi, B. T., Y. Zhang, and W. Zhang. 2018. “Analysis of the entire failure process of the rotational slide using the material point method.” Int. J. Geomech. 18 (8): 04018092. https://doi.org/10.1061/(ASCE)GM.1943-5622.0001211.

Soga, K., E. Alonso, A. Yerro, K. Kumar, and S. Bandara. 2016. “Trends in large-deformation analysis of landslide mass movements with particular emphasis on the material point method.” Géotechnique 66 (3): 248–273. https://doi.org/10.1680/jgeot.15.LM.005.

Sulsky, D., S. J. Zhou, and H. L. Schreyer. 1995. “Application of a particle in-cell method to solid mechanics.” Comput. Phys. Commun. 87 (Mar): 236–252. https://doi.org/10.1016/0010-4655(94)00170-7.

Trautmann, C. H. 1983. “Behavior of pipe in dry sand under lateral and uplift loading.” Ph.D. dissertation, Faculty of Graduate School, Cornell Univ.

Trautmann, C. H., and T. D. O’Rourke. 1985. “Lateral force-displacement response of buried pipe.” J. Geotech. Eng. 111 (9): 1077–1092. https://doi.org/10.1061/(ASCE)0733-9410(1985)111:9(1077).

Wang, D. Y., H. H. Zhu, B. J.Wang, and B. Shi. 2021. “Performance evaluation of buried pipe under loading using fiber Bragg grating and particle image velocimetry techniques.” Measurement 186 (Dec): 110086. https://doi.org/10.1016/j.measurement.2021.110086.

Wang, D.Y., H. H. Zhu, J.Wang, Y. J. Sun, L. Schenato, A. Pasuto, and B. Shi. 2023. “Characterization of sliding surface deformation and stability evaluation of landslides with fiber–optic strain sensing nerves.” Eng. Geol. 314 (Mar): 107011. https://doi.org/10.1016/j.enggeo.2023.107011.

Wu, J., G. Kouretzis, L. Suwal, Y. Ansari, and S.W. Sloan. 2020. “Shallow and deep failure mechanisms during uplift and lateral dragging of buried pipes in sand.” Can. Geotech. J. 57 (10): 1472–1483. https://doi.org/10.1139/cgj-2019-0281.

Xie, T. C., H. H. Zhu, C. X. Zhang, and W. Zhang. 2023. “Modeling strip footings on slopes using the material point method.” Bull. Eng. Geol. Environ. 82 (4): 99. https://doi.org/10.1007/s10064-023-03124-4.

Xie, X. C., F. Ceccato, M. L. Zhou, and D. M. Zhang. 2022. “Hydromechanical behaviour of soils during water-soil gushing in shield tunnels using MPM.” Comput. Geotech. 145 (May): 104688. https://doi.org/10.1016/j.compgeo.2022.104688.

Ye, X., H. H. Zhu, J. Wang, Q. Zhang, B. Shi, L. Schenato, and A. Pasuto. 2022. “Subsurface multi-physical monitoring of a reservoir landslide with the fiber-optic nerve system.” Geophys. Res. Lett. 49 (11): e2022GL098211. https://doi.org/10.1029/2022GL098211.

Yerro, A. 2015. “MPM modeling of landslides in brittle and unsaturated soils.” Ph.D. thesis, Dept. of Geotechnical Engineering and Geosciences, Universitat Politècnica de Cataluny, Barcelona.

Yerro, A., E. E. Alonso, and N. M. Pinyol. 2015. “The material point method for unsaturated soils.” Géotechnique 65 (3): 201–217. https://doi.org/10.1680/geot.14.P.163.

Yimsiri, S., K. Soga, K. Yoshizaki, G. R. Dasari, and T. D. O’Rourke. 2004. “Lateral and upward soil-pipeline interactions in sand for deep embedment conditions.” J. Geotech. Geoenviron. Eng. 130 (8): 830–842. https://doi.org/10.1061/(ASCE)1090-0241(2004)130:8(830).

Yost, K. M., A. Yerro, R. A. Green, E. Martin, and J. Cooper. 2022. “MPM modeling of cone penetrometer testing for multiple thin-layer effects in complex soil stratigraphy.” J. Geotech. Geoenviron. Eng. 148 (2): 04021189. https://doi.org/10.1061/(ASCE)GT.1943-5606.0002730.

Zhang, C., H. Zhu, and H. Li. 2023. “Modeling pipe-soil interaction under vertical downward relative offset using B-spline material point method.” J. Rock Mech. Geotech. Eng. 15 (6): 1520–1534. https://doi.org/10.1016/j.jrmge.2022.07.010.

Zhang, C. X., H. H. Zhu, W. Zhang, H. J. Li, and W. Liu. 2022. “Modeling uplift failure of pipes buried in sand using material point method.” Tunnelling Underground Space Technol. 119 (Jan): 104203. https://doi.org/10.1016/j.tust.2021.104203.

Zhang, X., Z. Chen, and Y. Liu. 2017. The material point method: A continuum-based particle method for extreme loading cases. Oxford, UK: Academic Press.

Zhu, H. H., T. C. Xie, W. Zhang, and S. K. Shukla. 2023. “Numerical simulations of a strip footing on the soil slope with a buried pipe using the material point method.” Int. J. Geomech. 23 (11): 04023190. https://doi.org/10.1061/IJGNAI.GMENG-8576.